Weighing & Packaging Line

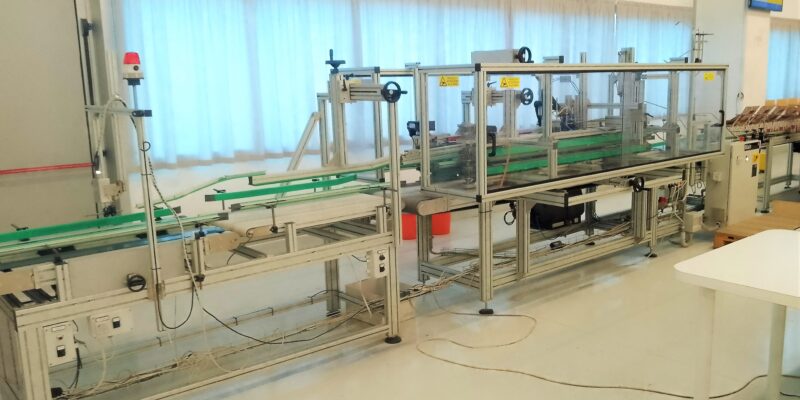

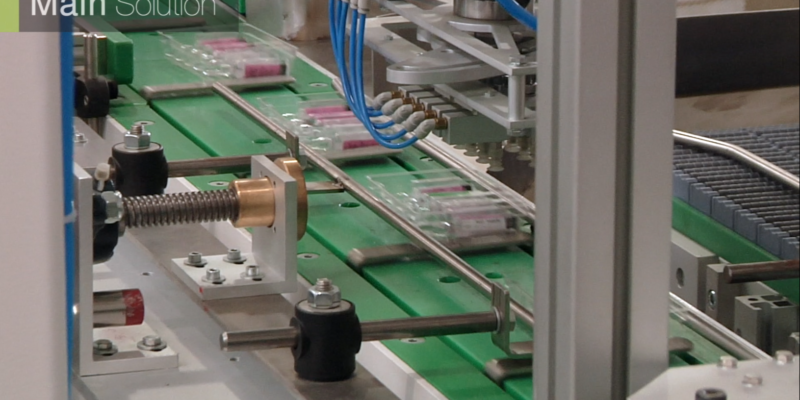

The Main Solution weighing and packaging lines suitable for the packaging of small metal parts, plastic parts and any small objects, etc. allow you to automate the dosing and packaging of these products, guaranteeing continuous control over the weight and any waste.

The Main Solution weighing and packaging lines can be composed of:

-

Box forming

-

Presentation tapes

-

Single or double head linear hoppers and vibrators

-

Weighing and unloading system

-

Vibration systems for settling the product inside the boxes

-

Weight verification and waste management system

-

Closure / Taping

-

Labeling

-

Palletization

-

Filming

The Main Solution weighing and packaging lines are made and designed to ensure quick and simple adjustments that allow the operator to change the format quickly by following the instructions in the manual and adjusting the moving parts to the indicated positions.

It is also equipped with safe access points to facilitate cleaning and maintenance.

All our machines are set up according to the provisions of industry 4.0.

GALLERY

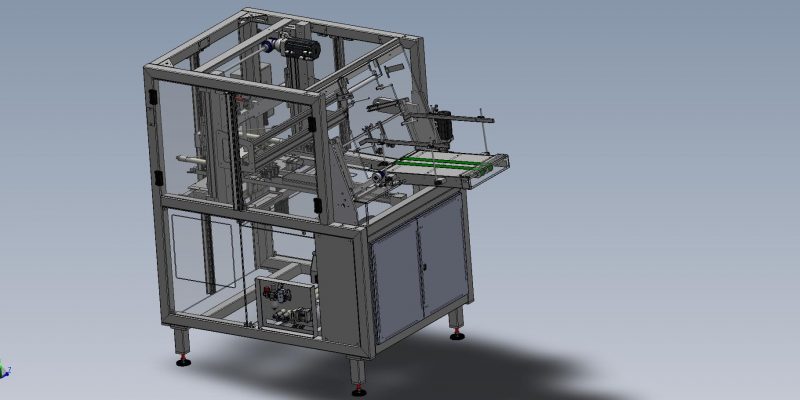

Forming Machines

Main Solution Forming machines are suitable for forming trays and cardboard boxes, starting from flat blank, with glue closure (hot melt), flap or interlocking.

The range of our machines is able to cover both mono-format and multi-format production needs.

Ease of maintenance, simple and quick format changes, studied on the needs of our customers, are some of the main features of our. cars.

Thanks to the use of 3 independent servomotors, our forming machines are able to guarantee flexibility and adaptability to the customer’s needs, as well as guaranteeing high production speeds.

All our machines are prepared according to the provisions of industry 4.0

FLOW CHART

GALLERY

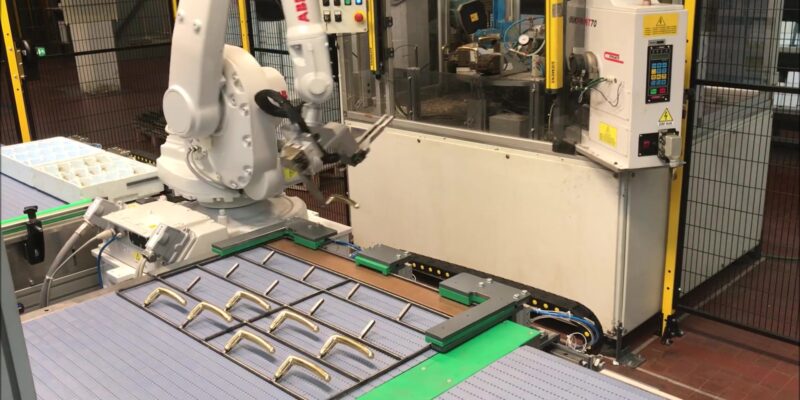

Industrial Robots

Industrial robots are used by companies to speed up production, making it more effective and efficient, optimizing costs and increasing the volume of products made.

Main Solution is specialized above all in the design of industrial robots which are used for painting and treating surfaces. Our items are available in multiple models, in order to meet the most specific needs of our customers. In fact, we offer tailor-made and customized solutions to ensure maximum efficiency, usability, precision and durability.

Industrial robots are intelligent automation and technical assistance systems that help manufacturing industries improving productivity and quality of their service improving the working environment also with regard to safety standards.

Industrial Robots: sectors and areas of use

Robotized or reciprocating systems are normally used in automatic painting systems and in general in surface treatment plants. Both robots and reciprocators are to be defined on the basis of the diversity of the shapes to be painted, the number of passes, the quantity of painted pistons.

The robots can be adapted to all painting systems and reciprocators are a valid alternative, cheaper but just as efficient and versatile, especially with regard to powder coating systems. Reciprocators can be vertical with long stroke, with short stroke or oscillating but all are managed by visual systems for the optimization of the strokes or guns needed.

GALLERY

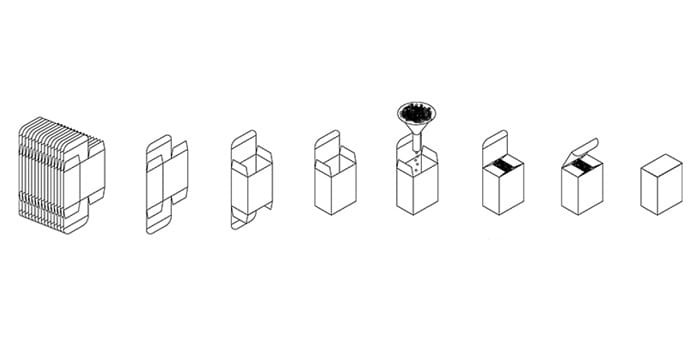

Carton Opener Machines

If you are looking for industrial carton opener machines, Main Solution is your ideal partner.

Our company is specialized in the design, construction and sale of these machines which are used for the automatic formation of cardboard boxes.

The machines pick up the cardboards, open them, fold them, form them and seal them following the best predefined cycle. They stand out for their precision, for the rapidity of movements, and the high efficiency by reducing the times of the individual processes.

Versatility is one of the strengths of our carton opener machines which are used to compose boxes of any type. Their particular structure allows to obtain customizations according to the characteristics of the cardboard, its use and customer needs.

What are the carton opener machines used for? Functionality and characteristics

Carton opener machines are a valid tool for speeding up industrial production and are more and more used in various product sectors. They are used precisely for the formation of cardboard boxes and trays which are then used for the packaging of the products.

The carton opener machines, starting from the flat cardboard with the relative folds, allows to obtain boxes with different types of closure of the bottom according to the type of product and the customer’s needs, obtaining closures: hooks, interlocking with flaps or with points of hot glue.

FLOW CHART

GALLERY

Cartoning Machines

The Main Solution cartoning machine is a compact machine, suitable for small environments that require low productivity with a high degree of flexibility and suitable for packaging various kinds of products in pre-glued boxes.

The Main Solution cartoner is made and designed to ensure quick and simple adjustments that allow the operator to quickly change the format by following the instructions in the manual and adjusting the moving parts to the indicated positions.

It is also equipped with safe access points to facilitate cleaning and maintenance.

Our machines provide for the possibility of providing manual or automatic loads and interlocking or glue (hot-melt) box closures.

All our machines are set up according to the provisions of industry 4.0

FLOW CHART

GALLERY

Conveyors

Main Solution offers to its customers a verified decades of experience in the design and production of conveyor belts for industrial handling.

Our machines can be used in various sectors from mechanical to food. Maximum efficiency, sliding speed, ability to work with other means according to the indications provided by those who use them. Main Solution offers models of conveyors tailor made and customized according to requirements.

Conveyor models offered by Main Solution

Main Solution is able to meet the various handling needs through various tools, capable of standing out for their efficiency and reliability:

-

Belt conveyors

-

Conveyors with roller shutter chain

-

Straight conveyors

-

Curvilinear conveyors such as belt conveyors, with slat, rectilinear or curvilinear chains.

GALLERY

Industrial Manipulators

Main Solution designs and build industrial manipulators that are used by companies to improve their production, optimize costs and improve efficiency.

The handling systems proposed by Main Solution are fully automatic and designed in close collaboration with our customers. This is why we are able to offer a customized movement and handling solution.

In more complex cases, where it is necessary for the details to be handled or manipulated to arrive at the gripping points in a random way, an innovative artificial vision system and dedicated software is able to identify the gripping position of the piece and then order the manipulator the right gripping coordinates. All stand out for their precision, efficiency and long life.

What are industrial manipulators and what are they used for?

Industrial manipulators are machines that are more and more used in the industrial sector because they speed up and facilitate the various processes.

Main Solution is appreciated for its ability to reduce production costs. These are automatic loading or pick & place stations that take products from a conveyor, conveying them to other machines or inserting them into special packages that will be subsequently closed.

The use of manipulators allows you to work safely reducing the risks of the various operators, the management of the lines is simplified, the service is made faster. It is the ideal solution to automate the grouping and loading of the various boxes. We offer several models that are customized to the requests and needs of our customers.

GALLERY

Machine Tending

Main Solution is specialized in the construction of special automated machines and plants. We take care of all phases from design to sale through production, thanks to which we are able to offer the latest generation of efficient, functional machines that can be adapted to the most varied circumstances on the market.

Our service is complete, designed to always guarantee maximum operational efficiency and aimed at the full satisfaction of each customer.

Machine tending is carried out using robots and aims to increase the productivity of a company. In fact, the robot works continuously and performs operations even without being manned. Their functionality can be modified according to the various production needs, always guaranteeing maximum efficiency, greater productivity and significant savings on the production line.

Machine tending systems: functionality and efficiency at your service

Main Solution produces systems for the tending t of work centers, transfers, lathes, presses, machine tools and systems in general.

Our company designs them in a personalized way so as to be able to respond to customer needs and the type of machine to serve. Machine vision systems are also available.

Robotic automation is used in tending machine on tools in order to guarantee our customers greater flexibility and the possibility to optimize the performance of the company. They can be supplied with auxiliary equipment in compliance of course with all current safety standards.

GALLERY